Raise Your Tools: Discover Costs Komatsu Undercarriage Parts Solutions

Raise Your Tools: Discover Costs Komatsu Undercarriage Parts Solutions

Blog Article

Reliable Solutions: Undercarriage Components for Heavy Equipment

Quality undercarriage parts play a considerable duty in ensuring the smooth operation and long life of hefty machinery. In this discussion, we will certainly discover the importance of investing in superior undercarriage components, usual wear challenges encountered by heavy equipment drivers, the advantages of timely substitutes, guidelines for picking reputable suppliers, and vital upkeep tips to prolong the life-span of undercarriage components.

Value of High Quality Undercarriage Components

Quality undercarriage components are necessary components in ensuring the sturdiness and efficiency of hefty equipment. The undercarriage of devices such as excavators, excavators, and track loaders plays a crucial function in supporting the device's weight, offering stability on various terrains, and absorbing the impact of irregular surface areas. By purchasing high-quality undercarriage parts, operators can substantially expand the lifespan of their machinery and lower the threat of unanticipated failures.

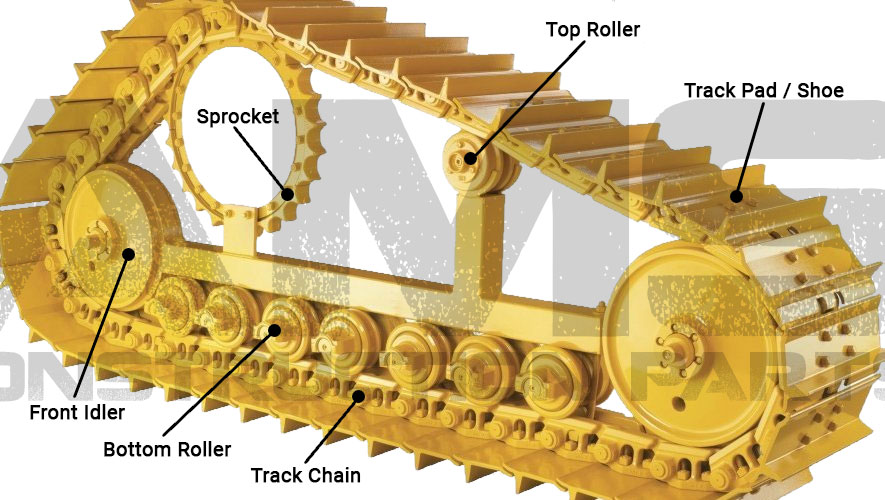

One trick advantage of utilizing quality undercarriage components is the improvement of general device performance. Sturdy tracks, sprockets, idlers, and rollers lower rubbing and make sure smoother motion, ultimately leading to raised efficiency and efficiency on work websites. Furthermore, reputable undercarriage components minimize downtime for repair and maintenance, enabling operators to optimize their operational hours and project due dates.

Typical Undercarriage Use Issues

Advantages of Timely Substitute

One trick advantage of timely undercarriage component replacement is increased maker uptime. By changing used parts prior to they fall short, the risk of unanticipated failures is reduced, lowering downtime for repair services and maintenance. This proactive strategy not just keeps the heavy machinery operational yet likewise stops possible damage to various other components that can arise from a falling short undercarriage.

Moreover, replacing undercarriage Get More Info parts quickly can enhance general productivity. A well-maintained undercarriage makes sure optimal device performance, enabling for smoother procedure and higher efficiency in completing jobs. This, consequently, leads to boosted job website productivity and price savings by staying clear of delays and disturbances triggered by underperforming equipment. Investing in prompt undercarriage part replacement is an aggressive technique that pays off in terms of boosted efficiency and minimized functional costs.

Selecting the Right Undercarriage Vendor

Picking the proper undercarriage distributor is a critical decision that substantially affects Resources the efficiency and maintenance of hefty equipment. When choosing a supplier for undercarriage components, a number of variables should be considered to ensure ideal performance and cost-effectiveness. A supplier that uses a broad choice of undercarriage parts for different hefty machinery brands and designs can be advantageous as it supplies extra alternatives to satisfy certain requirements.

In addition, reviewing the vendor's client service and support is vital. A distributor that uses outstanding client service, fast action times, and technical help can assist minimize downtime and make sure smooth operations. Expense is additionally a significant factor to think about; nonetheless, it ought to not be the sole factor. Balancing reliability, top quality, and cost-effectiveness is essential when choosing the ideal undercarriage vendor for hefty equipment. By carefully evaluating these elements, you can select a provider that satisfies your requirements and adds to the reliable efficiency and upkeep of your hefty machinery.

Upkeep Tips for Extended Life-span

To ensure a prolonged lifespan for hefty machinery undercarriage components, applying a positive upkeep regimen is important. Frequently inspecting undercarriage parts such as track chains, idlers, rollers, and sprockets for wear and tear is critical. Any type of indicators of damage or excessive wear should be without delay addressed to avoid additional deterioration and possible failures. Furthermore, maintaining the undercarriage clean from dust, debris, and destructive products can considerably lengthen its lifespan. Oiling relocating parts according to maker recommendations helps in reducing friction and stop early wear. Keeping an eye on track stress and positioning is additionally essential to stop unequal endure the undercarriage parts. Buying high quality undercarriage components from credible suppliers is similarly crucial for ensuring longevity. By complying with these upkeep pointers vigilantly, heavy equipment proprietors can maximize the efficiency and resilience of their undercarriage parts, eventually lowering downtime and functional costs.

Conclusion

In verdict, high quality undercarriage components are necessary for the efficient procedure of heavy equipment. Choosing a reliable vendor and following correct maintenance techniques are essential to making certain the prolonged life-span of undercarriage elements.

Too much wear and tear on undercarriage components of heavy machinery can lead to substantial functional difficulties and raised upkeep expenses. Regular inspections, correct upkeep, and timely replacements of worn undercarriage components are crucial to minimize these usual wear issues and guarantee the optimal performance of hefty machinery.

A supplier that provides a wide option of undercarriage parts for numerous hefty machinery brands and versions can be helpful as it offers more options to satisfy particular needs.

By adhering to these upkeep tips carefully, heavy equipment owners can optimize the efficiency and durability of their undercarriage components, ultimately decreasing downtime and functional expenses.

Report this page